Surface Coating Plants

Product Details:

Product Description

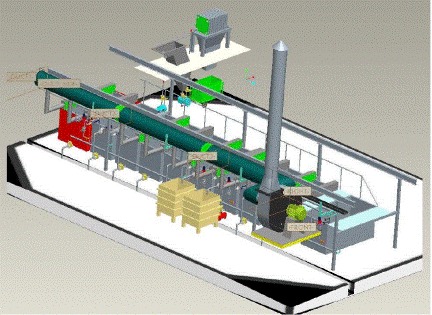

Surface Coating Plants

Blessed and supported by the team of high skilled and talented personnel, our company is considered as one of the leading service providers of Surface Coating Plants. Our offered services is highly preferred by the clients due to its timely execution, hassle free exclusion, reliability and cost effectiveness. Our team of professionals carries out this Surface Coating Plants service as per the specifications provided by our clients and that too at reasonable price.

Further Details

Stage 1 of CED : HOT WATER: Operating temperature of 55°-65°. This stage removes light surface oxides .

Stage 2 of CED : K.O.D: Alkaline Cleaner. Operating temperature of 55°-65°. This stage applies cleaner with oscillating spray nozzles to remove light surface oxides as well as any remaining lubricants.

Stage 3 of CED : DEGREASING: Alkaline Cleaner. Operating temperature of 55°-65°. This stage applies cleaner with oscillating spraynozzles to remove light surface oxides as well as any remaining lubricants.

Stage 4 of CED : R.O.WATER RINSE: Ambient operating temperature. This stage removes soils loosened by cleaner as well as removing cleaner residue.

Stage 5 of CED : R.O.WATER RINSE: Ambient operating temperature. This stage removes soils loosened by cleaner as well as removing cleaner residue.

Stage 6 of CED : SURFACE CONDITIONER: Ambient operating temperature. This stage prepares the cast/metal surface to accept the ZincPhosphate coating.

Stage 7 of CED : ZINC PHOSPHATE : Operating temperature of 40° - 45°. This stage applies a Trimetal Zinc Phosphate coating as a corrosion protective base for the paint coating.

Stage 8 of CED : DI WATER RINSE: Ambient operating temperature. This stage removes the Zinc Phosphate salts and stops Zinc Phosphate reaction.

Stage 9 of CED : DI WATER RINSE: Ambient operating temperature. This stage removes the Zinc Phosphate salts and stops Zinc Phosphate reaction

Stage 10 of CED : DI WATER RINSE: D.I. Water. Ambient operating temperature. This stage is a purifying rinse to remove excess phosphate and sealer. It lowers the surface conductivity of the part to prepare it for ecoating.

Stage 11 of CED : ELECTROCOAT BATH: Operating temperature of 28°(plus or minus 2°). This stage applies positive charged paint to a negativecharged part. This gives the part an electro deposition paint coating.

Stage 12 of CED : UF-1 (Ultra Filter): D.I. Water. Ambient operating temperature. This stage removes excess e-coat from the parts. It counterflows paint solids back to the e-coat tank to enable a high efficient operation

Stage 13 of CED : UF-2 (Ultra Filter 2): D.I. Water. Ambient operating temperature. This stage applies a permeate spray to assist in the removal ofexcess ecoat. It counter flows paint solids back to the e-coat tank to enable a high efficient operation.

Stage 14 of CED : DI WATER RINSE: D.I. Water. Ambient operating temperature. This stage removes excess e-coat from the parts. It counterflows paint. It Lowers the Surface conductivity of the par.

Stage 15 of CED : BANKING OVEN: Time :10 min, EMT: 160 Degree

Other Products in 'Surface Treatment Plants' category

Corporate Office:

834/1, Block-k, Mahipalpur,

New Delhi - 110037, India

Phone:91-11-26788114

Fax:91-11-26781200

|

|

|

|

KAMAL ENVIROTECH PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |